Employment:

- Cutting metal plates as pipes, double T beams, electrical towers and metal bars in scrap recycling centres.

- Demolition of oversized waste: railway wagons, tanks and compound metal structures even under water at shipyards/ oil platforms.

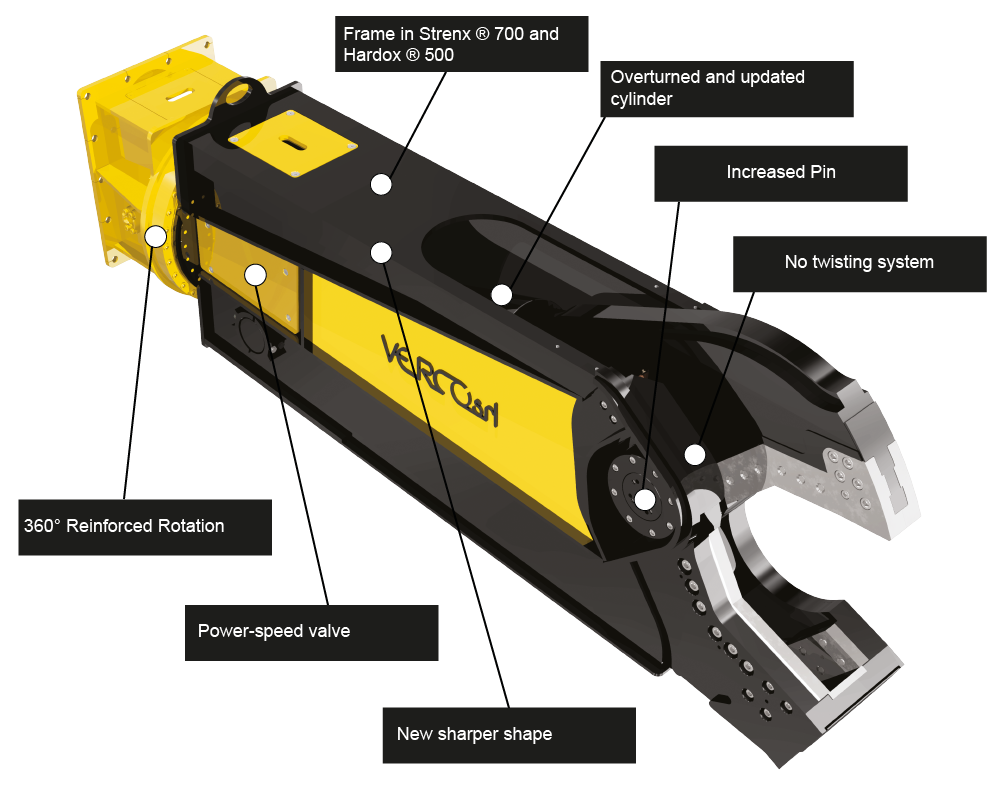

Frame:

- The whole structure is built with the best steels available on the market: Hardox ® 450/500 and Strenx ® 700 to minimize consumption and maintenance frequencies, so as to contain the costs of use.

- Super reinforced structure and long-limbed in the upper part to avoid distortions due to the side cutting to ensure greater penetration in the case of demolition complex structures on site

- Strengthened and overturned cylinder with longer stroke and with integrated power–speed valve to grant a quick job course, and protect the stem from wear (system fully designed by Verco srl).

- 360° hydraulic rotation equipped with geared motor, pressure control and anti-cavitation valves, in order to allow a fast positioning of the shear.

Mobile jaws:

- Fitted-in pin by liquid nitrogen guarantees perfect integrity and robustness in the body.

- Tip blades with no-shifting safety lock.

- Anti-restraining double guide blade, 4 time turning reversible.

- Cutting blades: ensure long-lasting and performant cutting edge, 4 time turning reversible.

- Provided by 2 misaligned pins working in constant thrust, to avoid twisting of the mobile body during high material resistance cutting phase.

mm

mm

lt

lt

kg

kg

ton

ton

mm

mm

mm

mm

mm

mm

mm

mm

t

t

t

t

mm

mm

mm

mm

t

t

t

t

l/h

l/h

bar

bar

l/h

l/h

bar

bar