Employment:

- Primary and secondary demolition of both vertical and horizontal concrete buildings.

- Decontamination and demolition of industrial sites and complex concrete infrastructures such as nuclear power plants, power stations and chemical plants.

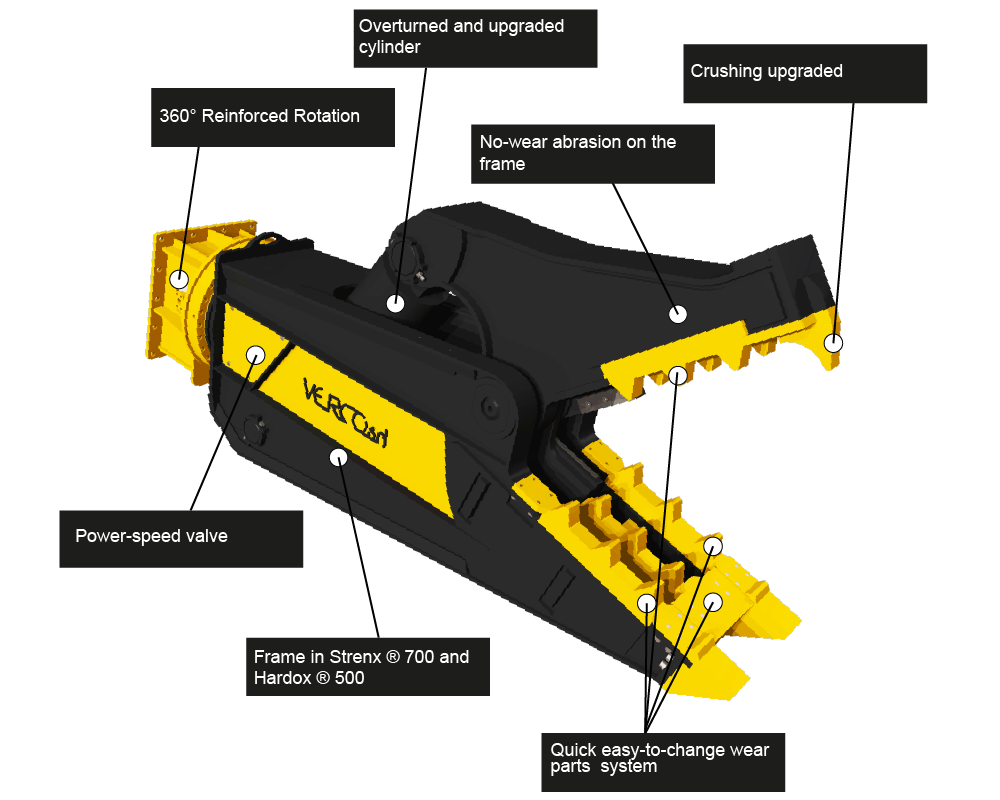

Frame:

- The whole structure is built with the best steels available on the market: Hardox ® 450/500 and Strenx ® 700 to minimize consumption and maintenance frequencies, so as to contain the costs.

- Strengthened and overturned cylinder with longer stroke and with integrated power–speed valve to grant a quick job course, protect the stem from continuous wear resulting from the impact against reinforcing steel bars and concrete frames (system fully designed by Verco srl).

- 360° hydraulic rotation equipped with geared motor, pressure control and anti-cavitation valves, in order to allow a fast positioning of the pulveriser.

- Designed to guarantee no wear on the structure. All parts areas involved in crushing are protected by interchangeable wear parts with quick disassembly.

Mobile jaws: it is built with particular attention on parts areas submitted to wear:

- Equipped by independent rows of interchangeable teeth in Hardox® 500 easy-to-dismount.

- Suited blades in Hardox® 500, for cutting concrete steel bars.

mm

mm

lt

lt

kg

kg

ton

ton

mm

mm

mm

mm

mm

mm

mm

mm

t

t

t

t

mm

mm

mm

mm

t

t

t

t

l/h

l/h

bar

bar

l/h

l/h

bar

bar