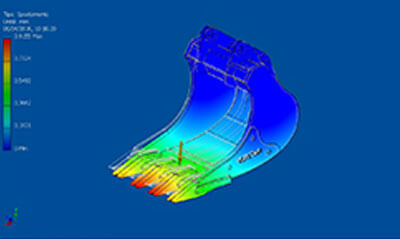

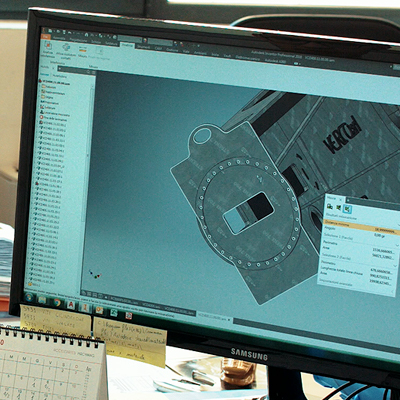

Design

Technical department is equipped by CAM-CAD 2D/3D engineering for drawing, and managing flame-cutting benches and CNC programs.

Cutting and chamfering

Our factory is provided by 3 flame-cutting benches along with 3 chamfering machines with capacity until 6000×2500 mm:

- n ° 1 combined oxygen/ plasma pantograph with cutting within water;

- n ° 1 high definition plasma pantograph with cutting within water;

- n ° 1 oxygen pantograph;

Deforming

Sheet metal plate transformation is one of our business brain centres.

This department is equipped by:

- n °1 three rolls hydraulic bending calender with capacity: 3000 mm / 400 tons.

- n °1 press brake with capacity 400 tons x 4000 mm.

Carpentry

Fleet of 6 bridge-cranes for handling products and tools, of which:

- n° 3 cap. 6,3 ton;

- n° 2 cap. 10 ton; ;

- n° 1 cap. 30 ton

Assembly department provided by 9 portable welding stations, MIG / MAG inverters and pulsed arc inverters and 1 painting booth

Mechanical processing

The machining department has been completely re-arranged in 2019 with the latest machineries on the market. In total we have:

- n ° 1 CNC computerized numerical control work bench 3000×2000 mm with tool changer

- n ° 1 CNC computerized numerical control work bench 3000×1000 mm with tool changer

- n ° 1 CNC computerized numerical control work bench 2000×1000 mm with tool changer

- n ° 1 CNC DOOSAN MYNX 9500 computerized numerical control work bench 2500×950 mm with tool changer;

- n ° 1 FAVRETTO 3000 CNC flat tangential grinding machine with 3000 x 1120 mm work surface;

- n ° 1 DAEWOO PUMA 350M lathe with CNC Fanuc, 3 axes + 1 motorized with ø380mm spindle drilled for ø90mm bar passage, maximum turning diameter 700mm for 1 length of 1050mm;

- n ° 1 traditional lathe;

Quality control

Each finished product is continuously submitted to strict quality controls through which processing stages. Non-destructive tests over the welding process guarantee high-advanced quality product.

The dimensional tests carry out with 1 portable measuring arm: ROMER Absolute 7530 with a 3 m measuring stroke, as well as roughness meters, hardness and micrometers, bore gauges and gauges of all sizes to ensure the proper process procedure.